we work through a clear, integrated process that connects design, technical resolution, and fabrication to deliver precise, buildable outcomes.

What Sets Us Apart

Design informed by making

Our design process is grounded in an understanding of materials, fabrication capabilities, innovative manufacturing methods, and assembly from the outset. By designing with how things are made in mind, we reduce inefficiencies and ensure ideas translate clearly from concept to physical outcome.

Prototyping as a design tool

We love getting our hands dirty. Prototyping is embedded throughout our process, not treated as a final step. Physical and digital prototypes allow us to test assumptions, refine details, and resolve challenges early strengthening design quality and confidence before final production.

Integrated Delivery

By maintaining involvement from early design through to fabrication, we retain control over quality, intent, and execution. This integrated approach reduces risk, shortens feedback loops, and results in precise, buildable outcomes delivered with clarity.

Define

Brief, intent, and constraints

Every project begins with a collaborative briefing process. We work with clients, designers, and stakeholders to establish design intent, functional requirements, budget, and fabrication constraints. Early technical input ensures that concepts are grounded in how they will be made, reducing risk and improving clarity from the start.

Design

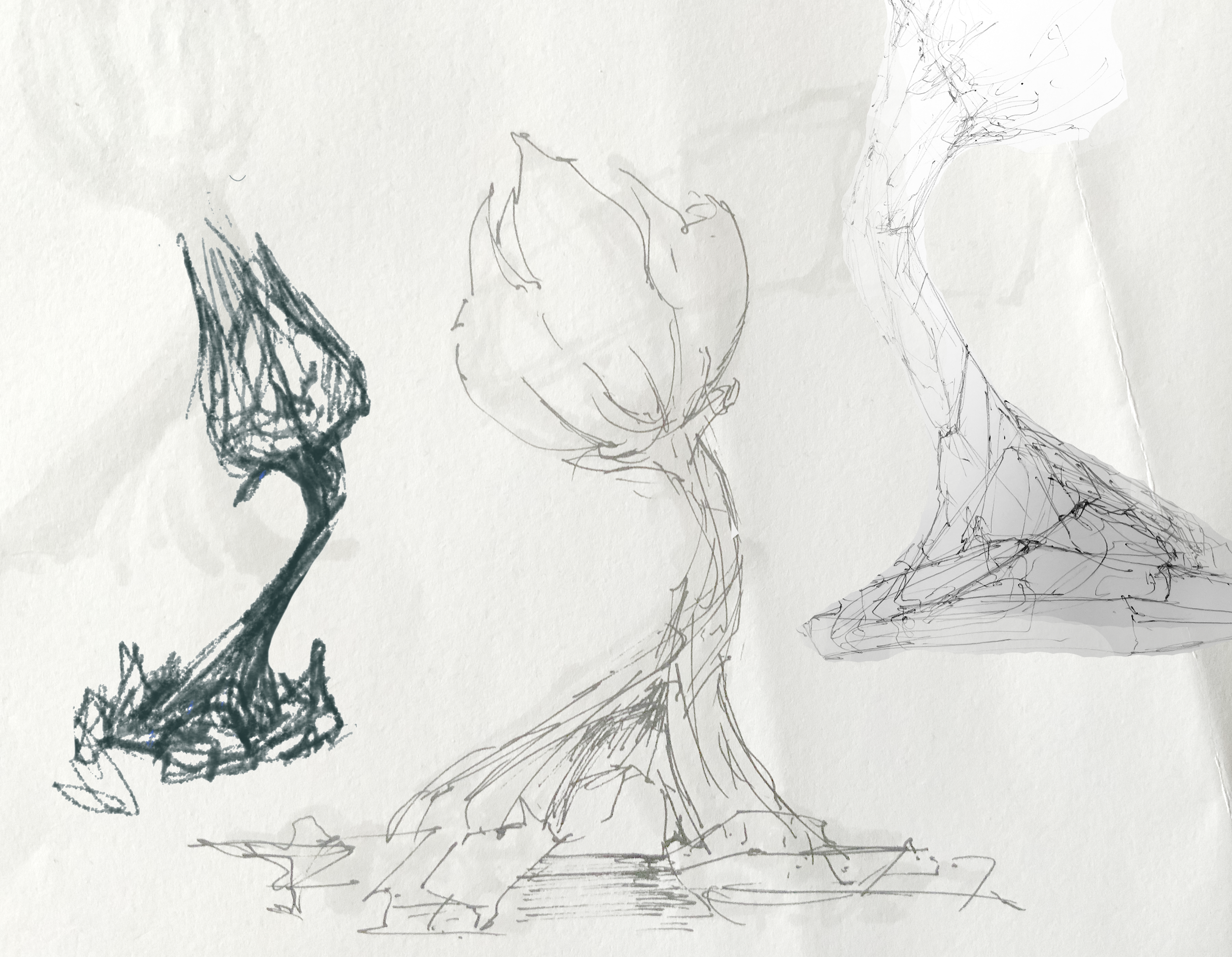

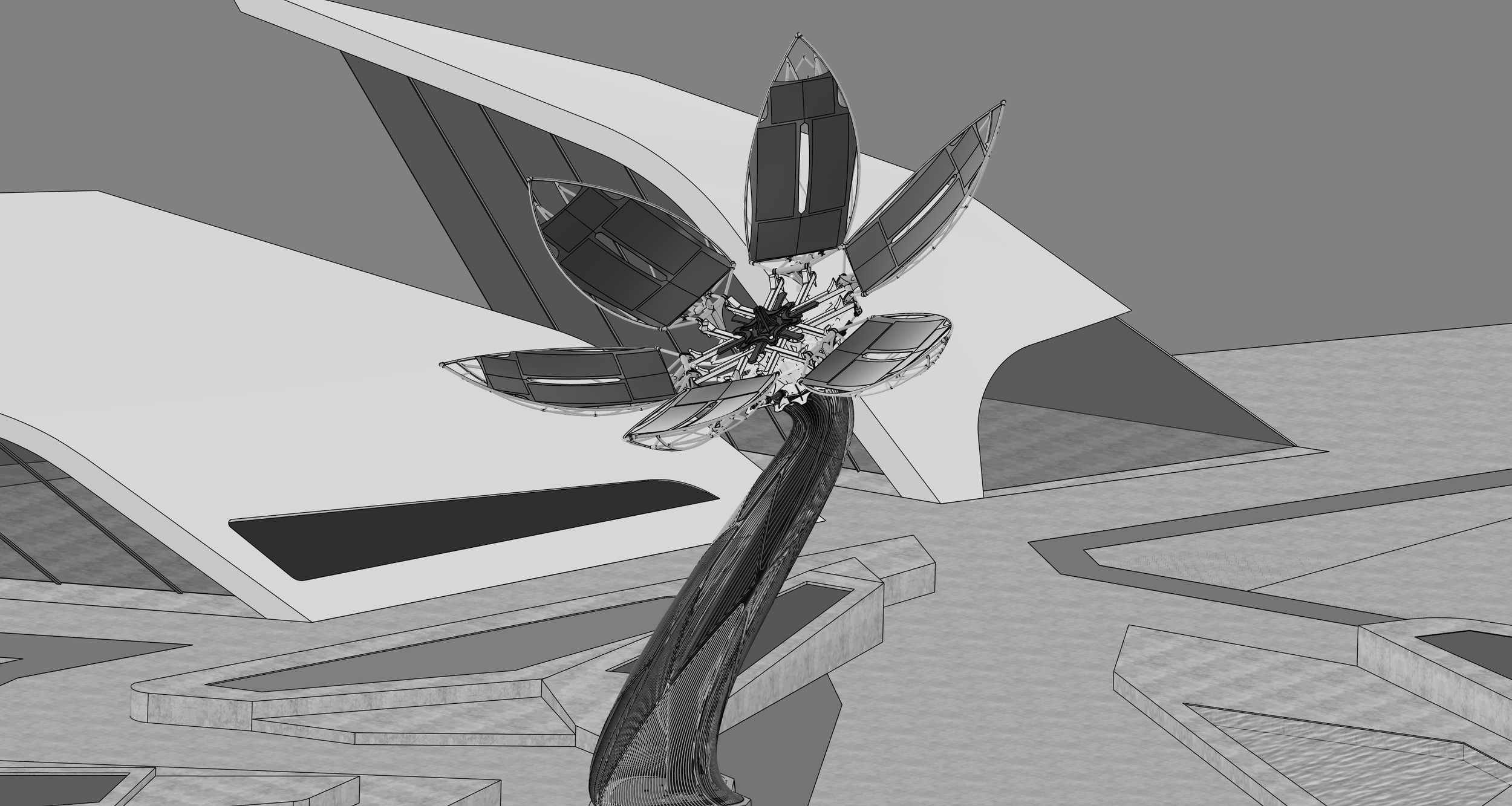

Concept Development and Iteration

Design ideas are developed through sketching, digital modelling, and iterative testing. Material behaviour, scale, and assembly logic are considered alongside form and expression, allowing design decisions to be informed by both creative and technical considerations.

Prototype

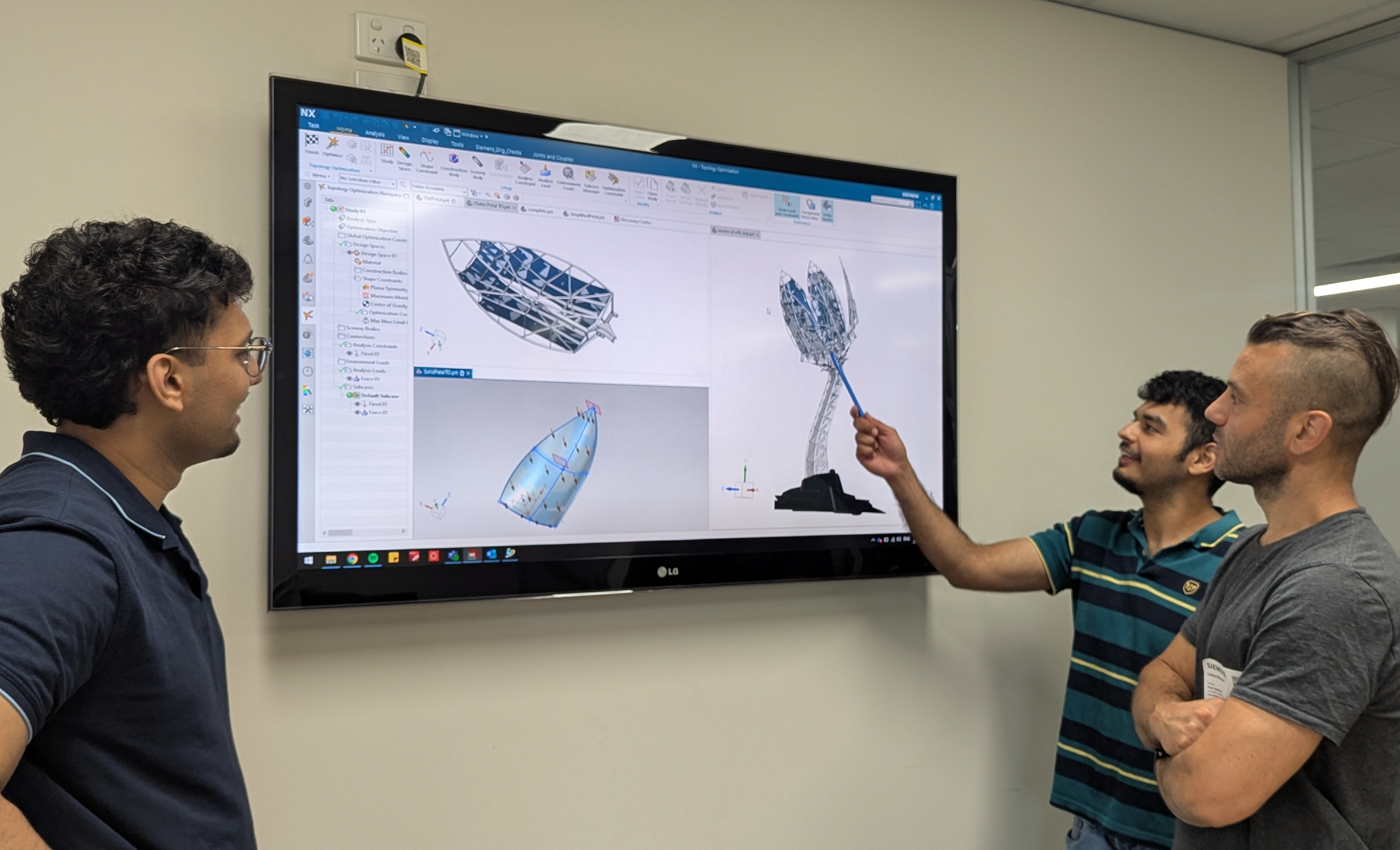

Test, Refine, Validate

Prototyping is central to our approach. We use physical and digital prototypes to test geometry, materials, detailing, and fabrication methods. This phase allows ideas to be refined through making, resolving challenges early and strengthening the transition to production.

Resolve

Technical Development and Documentation

Designs are technically resolved through detailed modelling and fabrication documentation. We address tolerances, connections, finishes, and installation requirements. We coordinate closely with clients and consultants to ensure designs are buildable and clearly communicated.

Fabricate

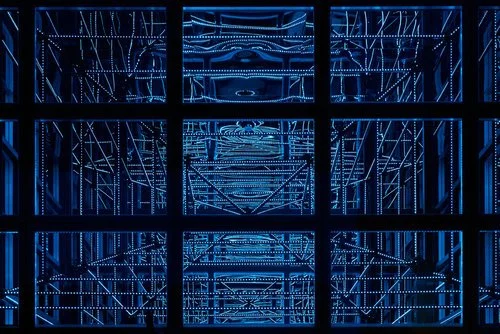

Make and Deliver

Projects are fabricated in-house or with trusted partners using a combination of digital and hand processes. We maintain design intent through to production, supporting assembly and installation where required to ensure outcomes are delivered with precision and care.